Controlling storefront and curtainwall water infiltration

Most architectural aluminum glazing systems are not designed to be totally waterproof. Rather, most systems are designed to control water infiltration under extreme conditions and weep that water back to the exterior. Storefront and curtainwall systems differ in many ways: appearance, profiles, wind load resistance, glazing, thermal performance and how they weep water. Let’s outline how storefront and curtainwall handle water disbursement differently.

Storefront

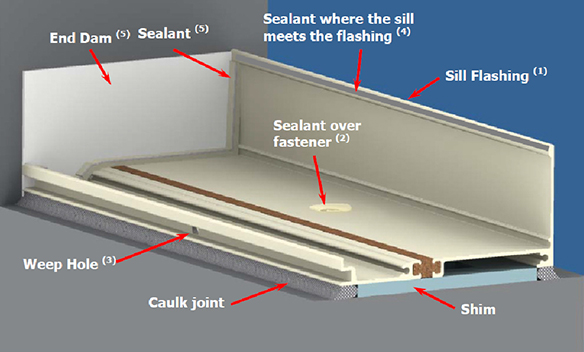

Storefront systems control water infiltration by directing all moisture to the sill flashing (1). It is imperative that the sill flashing be installed correctly. Most aluminum manufacturers have introduced high-performance sill flashing designs that allow the installer to fasten the flashing to the bottom of the opening prior to installing the storefront framing.

A watertight seal can then be applied over the fastener head (2). The sill then sets on top of the flashing with no need for fasteners penetrating the sill flashing (3). These extrusions also have a much higher back leg for better water performance, and it is important to make sure that sealant is applied to the top of the back leg prior to installing the sill (4).

Assuming that the sill flashing is installed correctly, the most important element in controlling water penetration with storefront is the proper fastening and sealing of end dams (5). Without end dams, water will intrude into the jamb locations of the building. In the photo below you can see where improperly (or missing) end dams have caused significant water damage to the interior drywall, even though sill flashing was present.

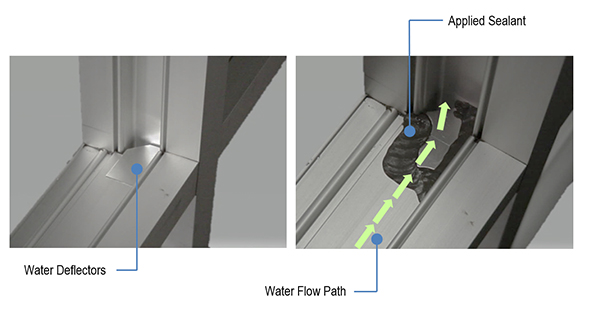

Water deflectors must be installed wherever a horizontal mullion occurs in storefront. These direct any water that reaches the horizontal over to the vertical mullion where it weeps out at the sill flashing. Deflectors are necessary to ensure that the water bypasses the lite of glass below the horizontal. Without water deflectors, moisture likely will settle on the top of the glass, allowing water to enter the interior and causing possible failure of the insulating glass unit.

Curtainwall

With curtainwall systems, we want to prevent any water from reaching the vertical mullion. Each horizontal mullion must have zone dams (sometimes called “joint plugs”) properly installed and sealed at the vertical. Any water that makes its way to the vertical mullion ultimately will end up on the interior of the building.

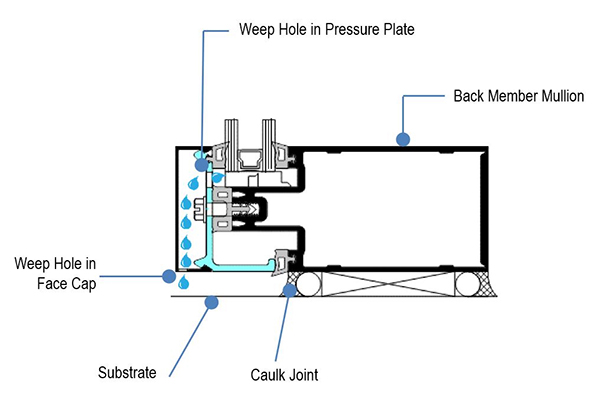

Unlike storefront, which directs all water to the sill, curtainwall weeps water at each individual lite of glass through holes in the pressure plate. Because most curtainwall systems are used on taller elevations with higher wind loads, the amount of water entering the system is typically greater than the capacity of strorefront mullions and sill flashing. This is why each lite of glass is individually weeped. There are critical steps that must be taken to ensure that no water penetrates a curtainwall system.

Each pressure plate must have three weep holes ABOVE the horizontal tongue. Additionally, each face cover requires a weep hole at each end of the daylight opening. All too often, field failures of curtainwall are directly due to improperly installed zone dams or incorrect placement or missing weep holes.

Since water is not directed down the vertical mullions to the sill, curtainwall does not require sill flashing. However, care must be taken in handling the caulk joints at the sill. The exterior caulk joint must be behind the face cover since water is weeping out of the bottom. A common installation error is mistakenly applying caulking to the exterior sill and blocking the weep holes.

So, how can you ensure that a storefront and/or curtainwall system is being installed correctly?

- Have the manufacturer’s installation instructions be included with the glazing subcontractor submittals. This will provide the architect, engineer and or general contractor a resource for field checking the installation, and they become part of the Construction Documents.

- Carefully review submitted shop drawings. Ensure that the details correspond with the manufacturer’s recommended installation instructions.

**

Brian Tobias is a LEED-accredited professional who serves as the senior manager of product strategy. Drawing from nearly 35 years of experience in architectural metal products and sustainable commercial building projects, he shares his knowledge with architectural, specifications and glazing industry professionals.

Please contact your client development manager for personalized assistance with an upcoming project, performance specifications and product installation instructions.

SHARE